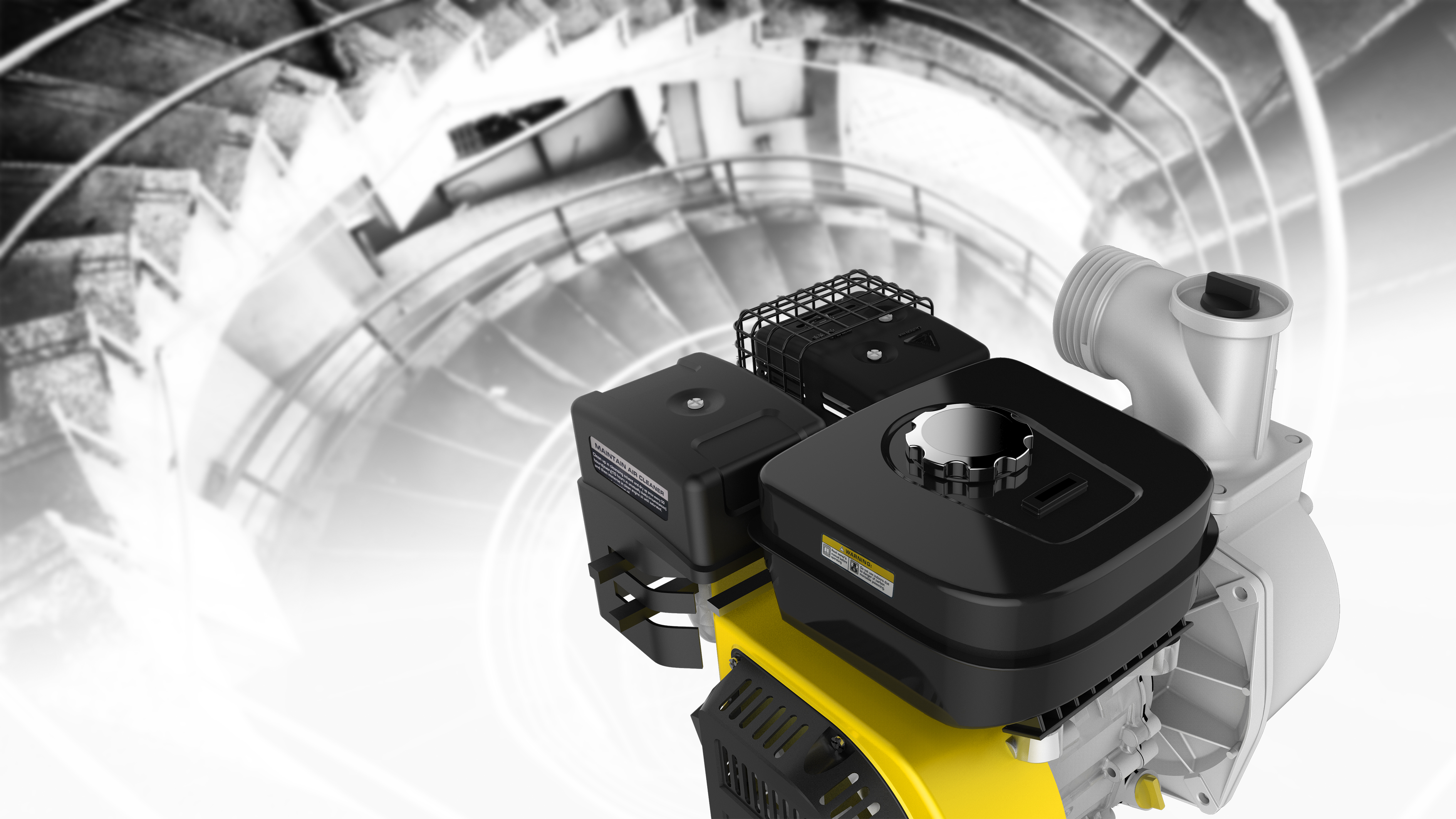

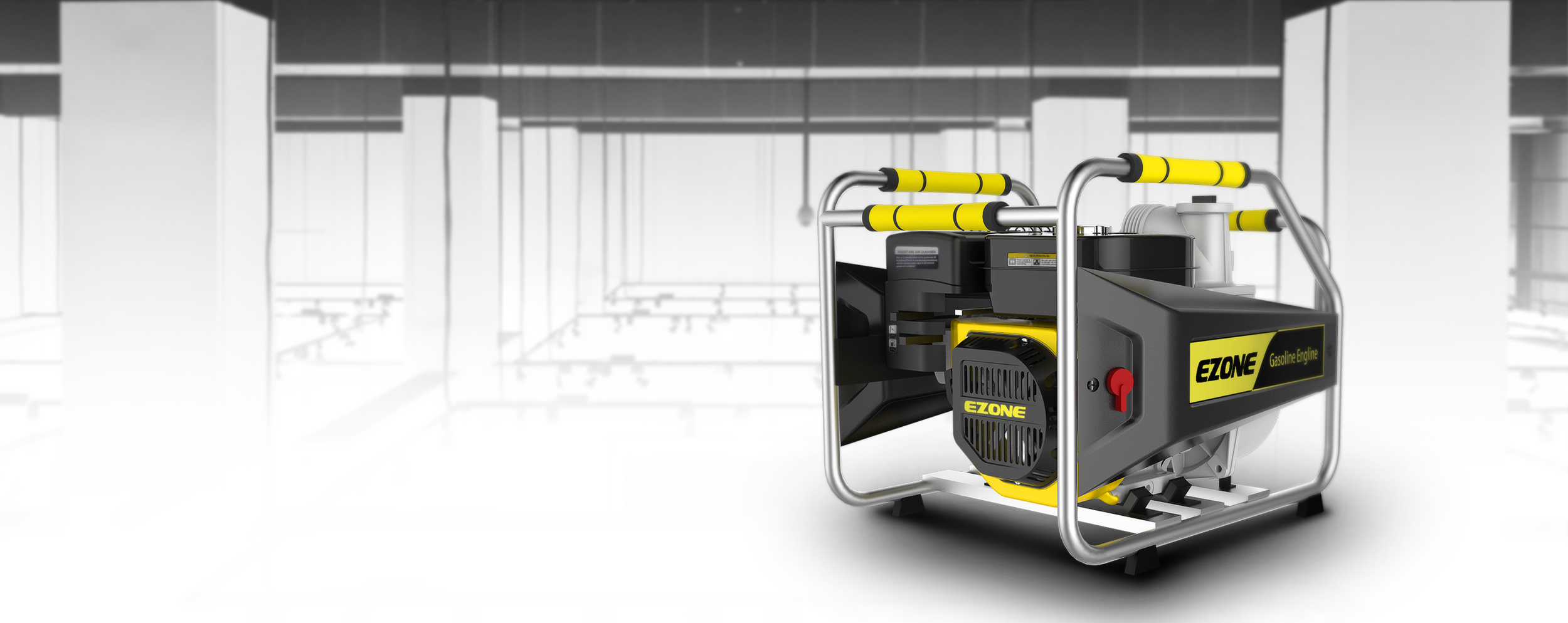

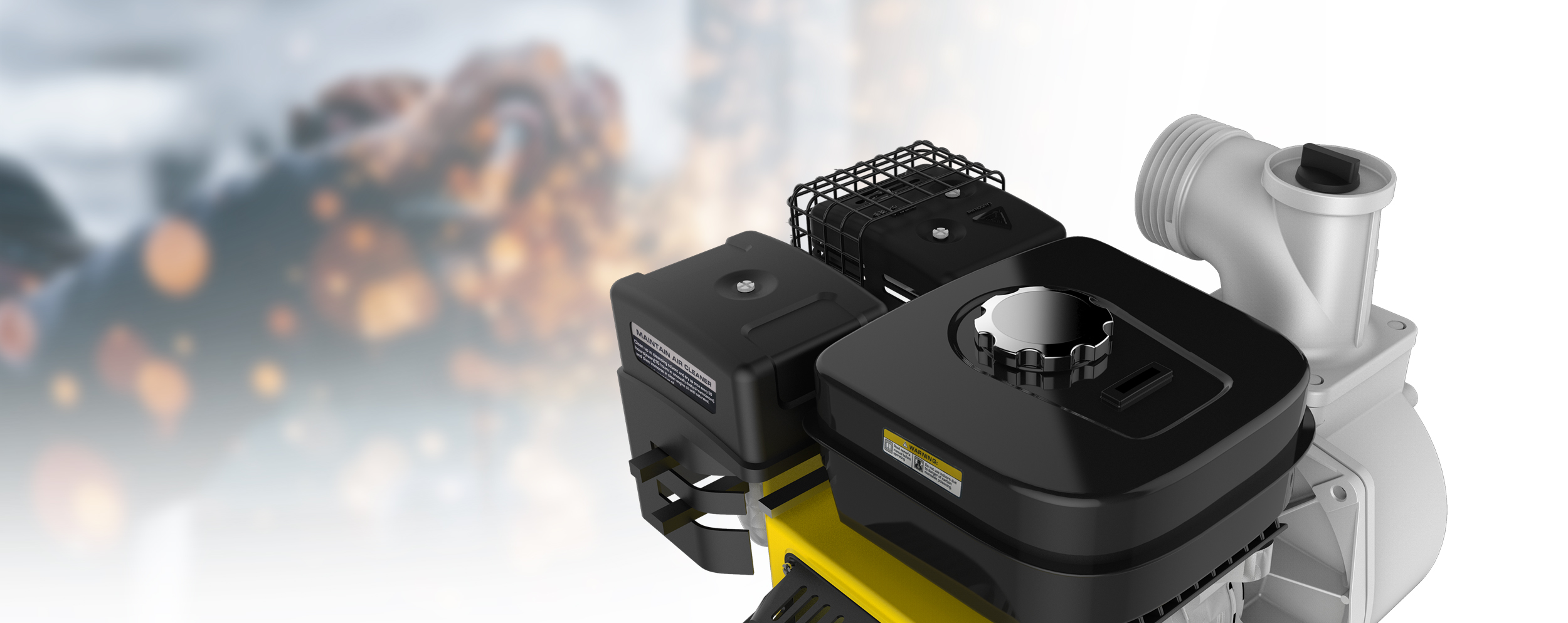

发电机-Gasoline generator

发电机主要应用于停电时段及取电不方便的场合。因考虑到散热、强度及生产成本,市面发电机大多采用标准管材折弯配合钣金冲压来制作整机框架及外壳。不同种类发电机的功率根据用电需求不同存在差异,从外形看来不同厂家的发电机最明显就是通过颜色区分。发电机的供电灵活性给我们的生活带来了很多的便利;重要的机房,大型冷库,医院、建筑工地等都备有发电机。

HURAKAN设计师综合考虑散热,强度及成本因素对益中的发电机进行了设计,醒目的配色让产品工业风十足,明显的logo标识搭配让系列化元素凸显,考虑到成本的可控框架及外壳的工艺依然采用常规方式,让客户快速实现了批量化生产销售。

Generator is mainly used in power failure period and inconvenient occasions. Considering heat dissipation, strength and production cost, most generators in the market adopt standard pipe bending and sheet metal stamping to make the frame and shell of the whole machine. The power of different types of generators is different according to the different demand for electricity. The flexibility of power supply of generators has brought a lot of convenience to our life. Important machine rooms, large cold storage, hospitals, construction sites and so on are equipped with generators.

HURAKAN designers consider heat dissipation, strength and cost factors on the evolution of generator design, eye-catching color let wind products industry, obvious logo logo series elements to highlight collocation, considering the cost control frame and shell technology still adopts the conventional method, let the customer quickly achieved mass production sales.